General “Musts”:

- Follow manufacturer’s installation, maintenance, and operation recommendations/specifications.

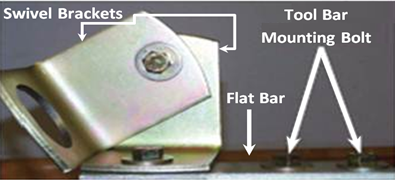

“Musts” for Double Swivel Brackets & Flat Bar:

- Swivel Brackets: Install bushings in both swivel bracket bolted connections to allow break-away coupling device (BACD) to move freely - generally 80 degrees side to side and 30 degrees up and down.

- Flat bar Installation:

- Two bolted connections to toolbar support.

- Single bolted connection to swivel bracket. This bolted connection is not to be connected to the toolbar support.

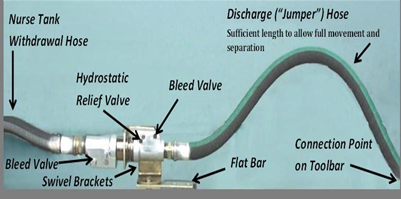

“Musts” for Other Components & Items Installed On/Around BACD:

- Bleed valves on both sides of BACD.

- 350-400 psi/NH3 rated hydrostat/rain cap when withdrawal hose is mounted on the toolbar and not the nurse tank.

- Discharge “jumper” hose must be long enough to allow full movement and separation of BACD - see mfg. specs.

- Toolbar components/components in assembly with the BACD must not impede the its operation.

- Display manufacturer-specific connection/disconnection instructions to be readily visible near the BACD. Parker-Pioneer requires both the aluminum ring around the female half of the BACD and the instruction decal posted near their BACD.

Recommended placement of BACD:

- Attach support holding the BACD assembly to toolbar frame - NOT the toolbar hitch.

- Position BACD as close as possible over the toolbar/nurse tank hitch connection point.

- Position BACD at least 24 inches above the toolbar/nurse tank hitch connection point during field application.

The goal of the last two recommendations is for maintaining consistent hose length through turns, free from entanglement.

Questions? Contact area NH3 Inspector or St. Paul Office

SC & SW MN – Bob Rialson @ (507) 746-4483

EC, SC, & SE MN – Jeff Lorentz @ (320) 223-6547

WC & NW MN – Jim Freilinger @ (320) 243-7382

St. Paul Office – Ed Kaiser @ (651) 201-6275